Super Concrete™

Cost-Effectiveness

-eng.png)

Super Concrete™

Product Line

| Classification | SUPER Concrete B | SUPER Concrete A | ||||

|---|---|---|---|---|---|---|

| SC801) | SC1001) | SC1201) | SC120f1) | SC150f1) | SC180f1) | |

| Target Compressive Strength (Design Standard Strength) |

80 MPa | 100 MPa | 120 MPa | 120 MPa | 150 MPa | 180 MPa |

| Manufacturing Method (Field/Factory)2) | Field (Factory) | Field (Factory) | Field/Factory | Field/Factory | Factory (Field) | Factory (Field) |

| Type (Con/FRC)3) | Con | Con | Con | FRC | FRC | FRC |

| Tensile Strength | (3.4 MPa)4) | (3.7 MPa)4) | (3.9 MPa)4) | 9 MPa5) | 12 MPa5) | 15 MPa5) |

| Bending Tensile Strength | 4~5 MPa | 6~7 MPa | 7~8 MPa | 20~35 MPa | 25~45 MPa | 30~55 MPa |

| Features | Economic efficiency, Versatility | Steel fiber reinforcement, maximum tensile strength, impact resistance, Explosion-proof performance | ||||

- 1)Compressive strength, manufacturing method, form, and tensile strength may vary depending on the required performance and type of the structure.

- 2)Field/Factory: Cast-in-place/Factory-made

- 3)Con/FRC: Concrete with coarse aggregate/Fiber-reinforced cement composite

- 4)CEB-FIP formula (split tensile strength)

- 5)Direct tensile strength

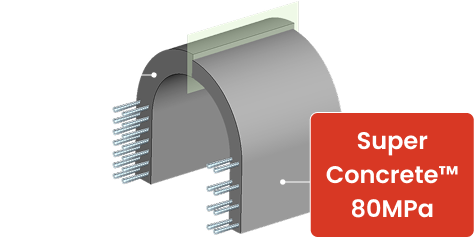

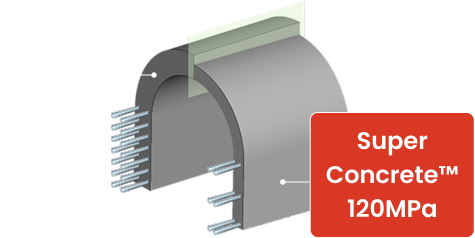

Advantages of SuperConcrete™ (80MPa / 120MPa) Compared to Regular Concrete

※ Defense Facility Application Cases

| Category |  |

|

|---|---|---|

| Concrete Volume | 10~30% ▼ | 30~50% ▼ |

| Reinforcing Steel Quantity | 20~50% ▼ | 70% or more▼ |

| Construction cost | 10~20% ▼ | 5% or more▼ |

| Carbon emissions | 40% or more▼ | 30~50% ▼ |

| Durability | 100% or more▲ | 200% or more▲ |

Super Concrete™ Solutions

We deliver Super Concrete™ solutions through SC mixers, batching plants, modular and OSC (off-site construction) production, as well as fire- and acid-resistant technologies and the use of special admixtures.

Development of On-site Customized Manufacturing and Curing Technologies, Applied in Diverse Domestic and International Projects

| Field | Manufacturing Method | Curing Technology | Compressive Strength |

|---|---|---|---|

| USA Hawkeye Bridge | Ready-mix concrete truck mixer | 40~50℃ | 180MP |

| Myanmar Ka-Tae-Myung Bridge | Ready-mix concrete truck mixer | Bubble Sheet Curing | 150MPa |

| Chuncheon Bridge | Field BP | 80℃ | 180MP |

| Ulleungdo Healing Place Cosmos Resort | Ready-mix concrete plant + Ready-mix concrete truck mixer | Dry Curing | 120MPa |

| Godeok Bridge | Ready-mix concrete plant | Wet Curing | 80MPa |

| Gwangmyeong Cave VR Experience Center | Ready-mix concrete plant + Ready-mix concrete truck mixer | Dry Curing | 120MPa |

| Vietnam File Products | Factory General Mixer | 40~50℃ | 120MPa |

| General Bridge | Factory General Mixer | 40~50℃ Wet Curing | 80~150MPa |

| Architectural interior and exterior finishes | Factory General Mixer | Dry Curing | 120MPa |

| Livestock products | Factory mixer | 60~80℃ Wet Curing | 100~150MPa |

Domestic and Overseas Portable Plant

(Transportable in container boxes)

Output per hour : 36m³ / Using 2 Mixers

Ready-Mix Drum Mixer Batch Production

Output per hour 20㎥ / 1 ready-mix truck

Achieves 188MPa after 3 days of normal curing (at 40~50 °C) without steam curing