Super Concrete™ Technology Description

Super Concrete™ technology refers to the material, production, design, fabrication, construction, guidelines, and standard technologies for ultra high performance concrete (UHPC). This was developed by Dr. Byung-Suk Kim, founder and CEO of SuperCon Lab (established July 2025) and with his colleagues during his service at KICT from 1984 to 2024.

While at KICT, Dr. Kim led major government-funded projects: "BRIDGE 200" (2002–2006), "SUPER Bridge 200" (2007–2011), and the national R&D group "SUPER Structure 2020" (2012–2019), carrying out UHPC research with a total budget of KRW 52.4 billion.

The result is SCⒶ (Super Concrete A, 120 MPa–180 MPa), a type of UHPC, and SCⒷ (Super Concrete B, 80 MPa–120 MPa), defined as ultra high strength concrete. These cover all aspects from material and manufacturing to structural design, production, construction, guidelines, and codes.

During the research project, technology was accumulated through over 7,000 specimen tests and 600 member tests, while 17 sets of Korean and English design, fabrication, and construction guidelines and standards dedicated to super concrete were developed.

Additionally, it has been applied to over 100 domestic and international structures. It constructed the Chuncheon Bridge, the world's first UHPC cable-stayed bridge achieving a quantum leap record of 180MPa (previous technology was around 45MPa). We built the 'Ulleungdo Healing Stay Cosmos' resort, the world's first UHPC building and the world's first building without steel reinforcement. We also constructed the Godeok Grand Bridge, the world's longest span concrete bridge with a 540m span length. Furthermore, we have achieved a track record of applying these technologies to over 100 sites domestically and internationally. These technologies also earned us the sole award in both the 'Infrastructure' and 'Building' categories at an international innovation competition.

This is truly South Korea's world-class concrete technology, a new innovation that can open new paths for the present and future of architectural and infrastructure facilities, as well as for strengthening global competitiveness.

Core Performance and Technical Differentiators

Super Concrete™ Technological Innovation

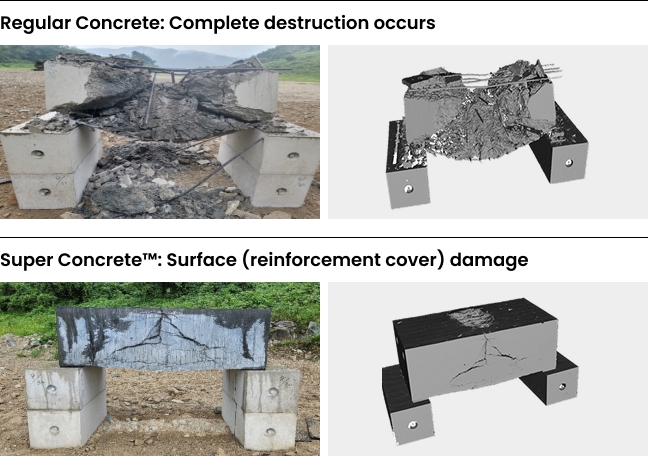

- Ultra-high strength (compressive 80–180 MPa, tensile 9–15 MPa, flexural tensile 23–53 MPa)

- Ultra-durable (over 200 years)

- World's lowest shrinkage (500 micrometers or less)

- Fire resistance exceeding 3 hours

- Pumping performance equivalent to standard concrete

Economic Feasibility/ Environmental Sustainability

- 10-20% reduction in construction costs

- 70% reduction in rebar usage

- Carbon emissions reduced by over 40%

Enhanced Flexibility in Production and Application

- Establishing expertise in various production methods(On-site casting·factory production, Portable mixer development, Ready-mix concrete mixer mixing, Ambient curing, etc.)

- Small bridges, large bridges, buildings, interior and exterior finishes, and more—a wide range of applications

Development and Application of New Technologies for Reinforcing Aging Facilities

- SC technology development for strengthening aging bridge decks

- Development of SC technology for reinforcing aging bridge piers and foundations

※ SC(Super Concrete)

Development and Application of Innovative New Market Technologies and New Structural Technologies

- Development and supply of SC towers for Wind Power Generation

- Development and deployment of smart SC cabinets (underground transformers), hydrogen power generation containers, etc. development and deployment

NSC Development and Leadership, Continuous Position Securing

- 10% reduction in material costs compared to existing SC

- 10% improvement in material performance (compressive strength, tensile strength, elastic modulus, etc.)

- Promotion of ISO TC71 UHPC Standards

R&D and Achievements

R&D

-

Government-Funded Projects, National R&D (2002–2019, 50.6 billion KRW)

- 3 Reseach Groups

- 11 Major Research Projects

- Over 100 Sub-Projects

-

1.BRIDGE 200

Korea Institute of Civil Engineering and Building Technology, Institution’s Core Project- 2002–2006, 4.6 billion won

-

2.SUPER BRIDGE 200

Ministry of Science and ICT/Ministry of Science, ICT and Future Planning/Korea Institute of Civil Engineering and Building Technology, Institution’s Core Project- 2007–2012, 150 billion won

-

3.Super Concrete Structure 2020

Ministry of Land, Infrastructure and Transport/KAIA/Korea Institute of Civil Engineering and Building Technology, National R&D- 2002–2006, 31 billion won

OUTPUT

-

Academic

- SCI(E) Over 200 papers

- Non-SCI: Over 700 papers

- 6 international invited lectures

- Published in ASCE invited papers

-

Domestic and International Standards, Specifications, Guidelines, Manuals, Design Example Collections

- Korean: 32 types

- English: 6 types

-

Intellectual Property

- Over 100 domestic and international patents registered

- 4 designated new technologies

- 63 software registrations

-

Experiments and Demonstrations

- Over 7,000 material tests

- Over 600 component tests

- Over 100 Prototypes and Pilot Models

-

Promotion of International Standardization

- Pursuing the establishment of a new subcommittee related to ISO TC71

- Reflecting the Asian Code

- Incorporation of fib (European Concrete Institute) UHPC bridge design examples

- 6 international invited lectures

-

Media and Technical Promotion

- Over 100 media reports including NBC (US), KBS (Korea), YTN

-

Dissemination of Achievements through Technical Briefings, Seminars, and Exhibitions

- 11th Training Program for construction officials from developing countries including Myanmar, Vietnam, and India

- Briefing session for top 3 U.S. design firms

- Briefing for the U.S. Federal Highway Administration

- 13 events including briefings and exhibitions for domestic construction companies

OUTCOME

-

Technology Transfer

- 27 technology transfer implementation contracts

- 23 cases of small business trade implementation

- 4 standard licenses for special structures with large corporations

- Daelim E&C (Legoland Bridge)

- Hyundai Engineering & Construction (Godeok Bridge, Yeongdong-daero Underground Project)

- Kolon Global (Healing Stay Cosmos)

-

Commercialization

- Reinforcing fibers

- Pre-mixing binder

- High-performance water-reducing agent, shrinkage-reducing agent, air-entraining agent

- Other items (9 total)

-

Field Application

- Applied to over 100 domestic and international sites

- TTotal construction cost: over 300 billion won

- Domestic: Bridges, buildings, cladding, sculptures, etc.

- Hawk Eye Bridge, USA

- Myanmar Highway Expansion Bridge: Khatumang Bridge

IMPACT

-

Economic Impact

- 70% reduction in manufacturing costs compared to existing UHPC technology

- Over 10% reduction in long-span bridge construction costs

- Reduction of over 10% in life-cycle costs

-

Social Impact

- Over 40% reduction in carbon dioxide emissions

- Reduction of natural resource usage (aggregates, limestone, etc.) by 30% or more

- Reduction in construction waste due to extended facility lifespan

- Enhanced aesthetics of civil engineering and architectural structures

Super Concrete™ Excellence

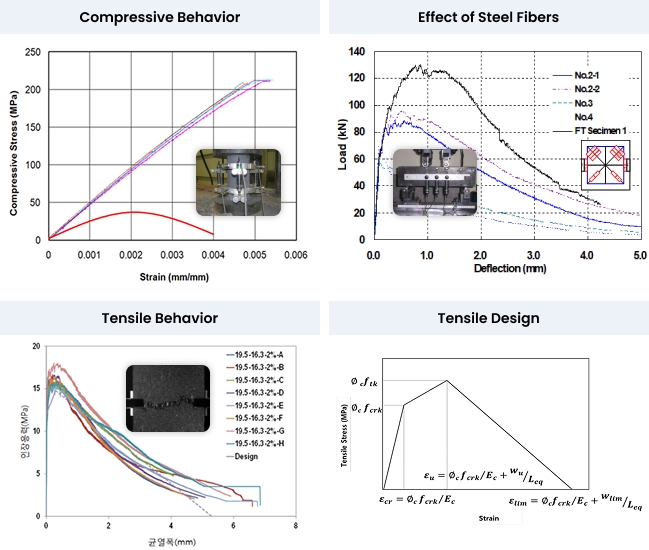

Ensuring Reproducibility and Reliability through Diverse Experiments

Over 7,000 material tests and over 600 full-scale member tests for developing design and construction guidelines

World’s Largest Collection of Standards and Guidelines

32 Korean, 4 English

-

Design Guidelines of 180MPa SUPER Concrete (Kor, 2014.07.)

-

Design Guidelines of SUPER Concrete (120, 150, 180MPa) (Kor, 2015.06.)

-

The Structural Design Guideline of SC80 SUPER Concrete (Kor, 2017.04. revised)

-

The Structural Design Guideline of Fiber Reinforced SUPER Concrete (Kor, 2019.06.)

-

Design Guidelines of K-UHPC (Eng, 2014.04.)

-

Design Guidelines of SUPER Concrete (Kor, 2019.06.)

-

The Structural Design Guideline of SC80 SUPER Concrete (Eng, 2016.06.)

-

The Structural Design Guideline of Fiber Reinforced SUPER Concrete (Eng, 2016.06.)

-

The Structural Design Guideline of Fiber Reinforced SUPER Concrete (Eng, 2016.06.)

-

The Structural Design Guideline of SUPER Concrete (Eng, 2017.08.)

-

Design Guidelines for Bridge Superstructures Using SUPER Concrete (Draft) (Kor, 2018.07.)

-

Specification for Manufacturing SUPER Concrete Using Coarse Aggregate (Kor, 2018.05.)

World’s Best Tensile Strength

Maximum tensile strength of 19.1 MPa among comparable products (1.6 times that of France's Ductal, 1.3 times that of the US's T-UHPFRC)

- Achieves world-leading tensile strength despite using less steel fiber than foreign UHPC

- Utilizes hybrid fibers to enhance crack resistance and tensile deformation performance

![[SUPER Concrete 인장강도]](/wp-content/uploads/tech1_con4_col3_img1-en.jpg)

![[Hybrid 섬유 사용 변형능력]](/wp-content/uploads/tech1_con4_col3_img2-en.jpg)

* Related Publications

Cement & Concrete Composite 34(2), Tensile behavior of ultra high performance hybrid fiber reinforced concrete

Composite Structures 145, Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete

Composite Part B: Engineering 58, Size and geometry dependent tensile behavior of ultra-high-performance fiber-reinforced concrete

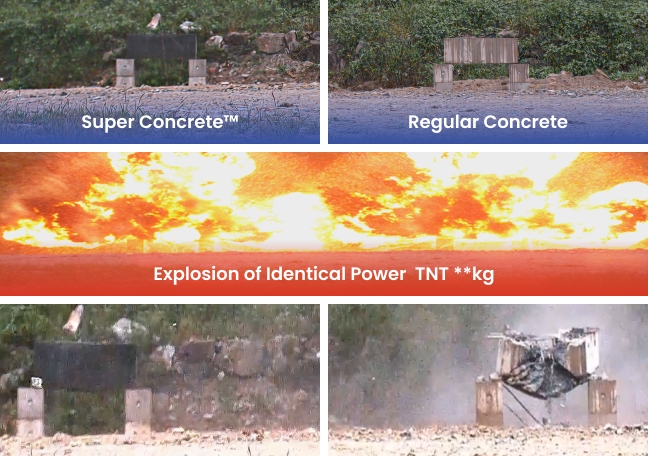

Explosion-Proof Performance Testing of Super Concrete™

Explosion-Proof Testing

- Location: Army Engineer School Test Site, Jangseong, Jeollanam-do

- Test Variables: Concrete Type (Standard (30MPa), Super (180MPa)), Test Specimen Thickness (700mm, 300mm)

- Explosive Conditions: Explosive charge equivalent to standard concrete failure level (** lb), direct contact detonation on top surface of test specimen